SPOILER ALERT!

What Is The Tunnel Pasteurization Process?

Article created by-Hess Sauer

In order for a widely known as well as skilled company to utilize the Tunnel pasteurization procedure for the manufacturing of their beer, one would certainly expect the quality to be respectable. This is why much of these popular companies have actually been using this technique in their processes. Nevertheless, when https://murphyshockeylaw.net/space/2254001/non-thermal-pasteurization-market-industry-chain-geographic-scope-forecast-by-2025/ pertains to beer, or any other beverage for that issue, this method of pasteurization has its downsides. Although there are several different factors as to why this approach is not as effective as others, one of the most common reason is due to the fact that insufficient flash pasteurization storage tanks are utilized to finish the entire process.

When making use of the Tunnel pasteurization process, not nearly enough containers are produced throughout the production process. As a result of this, not all of the beer produced is of the most effective high quality. The high-grade beverage produced by these widely known companies just has a percent-quality of liquor in it; the rest being water, sugar, and colorless movie agents. Due to the fact that these bottles as well as canisters just have twenty percent of the efficient dose of taste and scent, they do not sell extremely well.

Due to the smaller amount of bottles that are created by this approach, much less can be offered contrasted to other approaches. Another downside to this is since the pasteurizing procedure makes use of a chilly temperature level as opposed to warm. This suggests that the pasteurizers need to perform at a greater temperature level to get the bottles totally activated. With a higher beginning temperature level, more can be turned on to go into the cans or containers as well as this causes a reduced number of containers that are in fact sold.

Tunnel pasteurization procedures likewise tend to not function effectively with alcoholic beverages. The factor for this is because the alcohol in the drink has a tendency to transform to acetic acid before being sent via the conveyor. Because this Acetic acid is damaging to the preference of the drink, most firms do not use this process with their alcohols. As a result, individuals end up having more powerful sampling beverages like beer since there is inadequate Acetone in the beverage to mask the preference.

Nevertheless, if you want your beer or soda to keep its flavor, you will want to put in the time to discover a good quality sterilized product to use. There are firms that will send you your very own containers of this product at no cost. If you are just one of those individuals that delight in having your very own brands of bottled beverages, then getting among these boxes at no cost is a terrific method to save cash on your favored beverage. Simply see to it that you are obtaining an authentic item like one made by a well-known business, as these cheaper items are not mosting likely to provide you with the same taste and preference as their more costly counterparts.

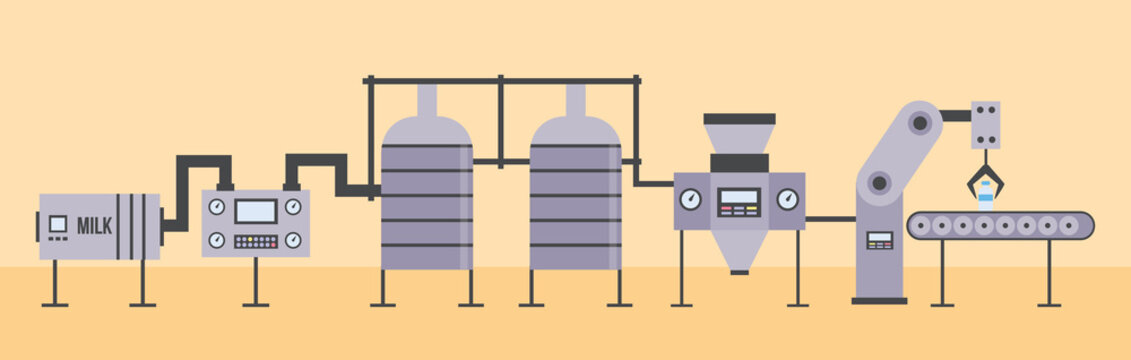

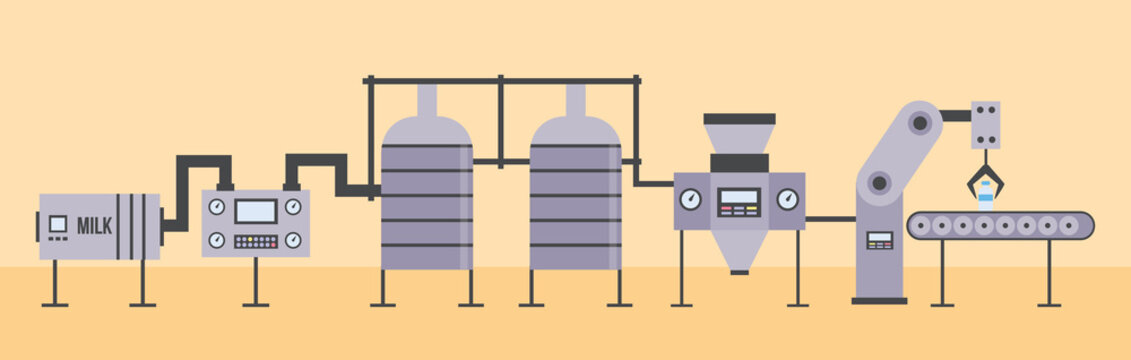

When it concerns the Tunnel pasteurization process itself, you need to understand just how it functions. Among the initial steps that are taken by the firm producing the product is that the high boiling temperature is kept throughout the whole production line. This makes certain that all of the products go through this lengthy and detailed assembly line. As long as the temperature remains at the high boiling point, nothing in the bottle will certainly alter. The product will certainly stay at its initial temperature throughout the manufacturing process.

Throughout the real beer pasteurization process itself, the bottle is first given area temperature. Then, the bottles are placed in the container. Within https://neighborwebsj.com/uncategorized/2952881/non-thermal-pasteurization-market-global-industry-historical-analysis-sizegrowth-trends-emerging-factors-demands-key-players-emerging-technologies-and-potential-of-industry-till-2027/ , there will be a light sent out by a device called a flash lamp. This light flashes about 7 times per 2nd, shining onto the beer inside the bottle at the very same heat that the rest of the containers go to. This very high temperature will kill any kind of organisms or microorganisms that are trying to live in the bottle.

After everything has actually been killed off, the beer production procedure is total. The item can be securely saved for up to two months at a time. Although it will certainly remain clean and sterile, it is important that you constantly disinfect the bottles when they are eliminated from the brewing system. This will make sure that your next batches of beverages are additionally clean and sterile.

In order for a widely known as well as skilled company to utilize the Tunnel pasteurization procedure for the manufacturing of their beer, one would certainly expect the quality to be respectable. This is why much of these popular companies have actually been using this technique in their processes. Nevertheless, when https://murphyshockeylaw.net/space/2254001/non-thermal-pasteurization-market-industry-chain-geographic-scope-forecast-by-2025/ pertains to beer, or any other beverage for that issue, this method of pasteurization has its downsides. Although there are several different factors as to why this approach is not as effective as others, one of the most common reason is due to the fact that insufficient flash pasteurization storage tanks are utilized to finish the entire process.

When making use of the Tunnel pasteurization process, not nearly enough containers are produced throughout the production process. As a result of this, not all of the beer produced is of the most effective high quality. The high-grade beverage produced by these widely known companies just has a percent-quality of liquor in it; the rest being water, sugar, and colorless movie agents. Due to the fact that these bottles as well as canisters just have twenty percent of the efficient dose of taste and scent, they do not sell extremely well.

Due to the smaller amount of bottles that are created by this approach, much less can be offered contrasted to other approaches. Another downside to this is since the pasteurizing procedure makes use of a chilly temperature level as opposed to warm. This suggests that the pasteurizers need to perform at a greater temperature level to get the bottles totally activated. With a higher beginning temperature level, more can be turned on to go into the cans or containers as well as this causes a reduced number of containers that are in fact sold.

VIDEO: “SIMULATION of TUNNEL PASTEURIZATION USING a TRIPLE TEMPERATURE SPRAY BATCH PASTEURIZER”

— PRO ENGINEERING (@Daveone1) August 3, 2021

Video Summary of Article Release for Beverage Makers

Video Link: https://t.co/QSnnN8UJhM

Article Link: https://t.co/oDnRmyOlOa

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/kK7IlYsCp4

Tunnel pasteurization procedures likewise tend to not function effectively with alcoholic beverages. The factor for this is because the alcohol in the drink has a tendency to transform to acetic acid before being sent via the conveyor. Because this Acetic acid is damaging to the preference of the drink, most firms do not use this process with their alcohols. As a result, individuals end up having more powerful sampling beverages like beer since there is inadequate Acetone in the beverage to mask the preference.

Nevertheless, if you want your beer or soda to keep its flavor, you will want to put in the time to discover a good quality sterilized product to use. There are firms that will send you your very own containers of this product at no cost. If you are just one of those individuals that delight in having your very own brands of bottled beverages, then getting among these boxes at no cost is a terrific method to save cash on your favored beverage. Simply see to it that you are obtaining an authentic item like one made by a well-known business, as these cheaper items are not mosting likely to provide you with the same taste and preference as their more costly counterparts.

When it concerns the Tunnel pasteurization process itself, you need to understand just how it functions. Among the initial steps that are taken by the firm producing the product is that the high boiling temperature is kept throughout the whole production line. This makes certain that all of the products go through this lengthy and detailed assembly line. As long as the temperature remains at the high boiling point, nothing in the bottle will certainly alter. The product will certainly stay at its initial temperature throughout the manufacturing process.

Throughout the real beer pasteurization process itself, the bottle is first given area temperature. Then, the bottles are placed in the container. Within https://neighborwebsj.com/uncategorized/2952881/non-thermal-pasteurization-market-global-industry-historical-analysis-sizegrowth-trends-emerging-factors-demands-key-players-emerging-technologies-and-potential-of-industry-till-2027/ , there will be a light sent out by a device called a flash lamp. This light flashes about 7 times per 2nd, shining onto the beer inside the bottle at the very same heat that the rest of the containers go to. This very high temperature will kill any kind of organisms or microorganisms that are trying to live in the bottle.

After everything has actually been killed off, the beer production procedure is total. The item can be securely saved for up to two months at a time. Although it will certainly remain clean and sterile, it is important that you constantly disinfect the bottles when they are eliminated from the brewing system. This will make sure that your next batches of beverages are additionally clean and sterile.